Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

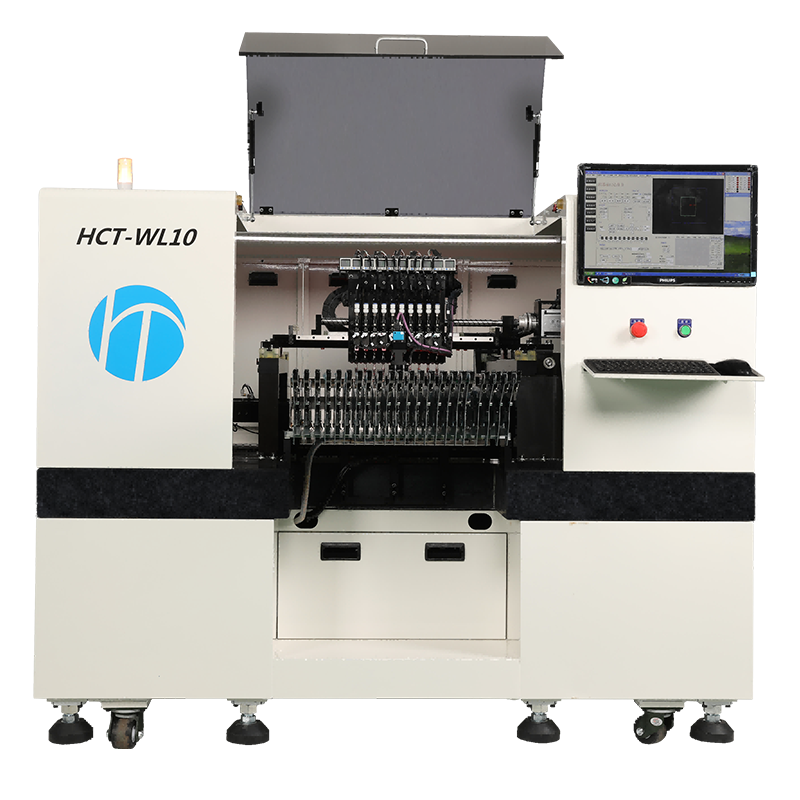

HCT-WL10 Automatic Copper Wire Lamp Placement Machine

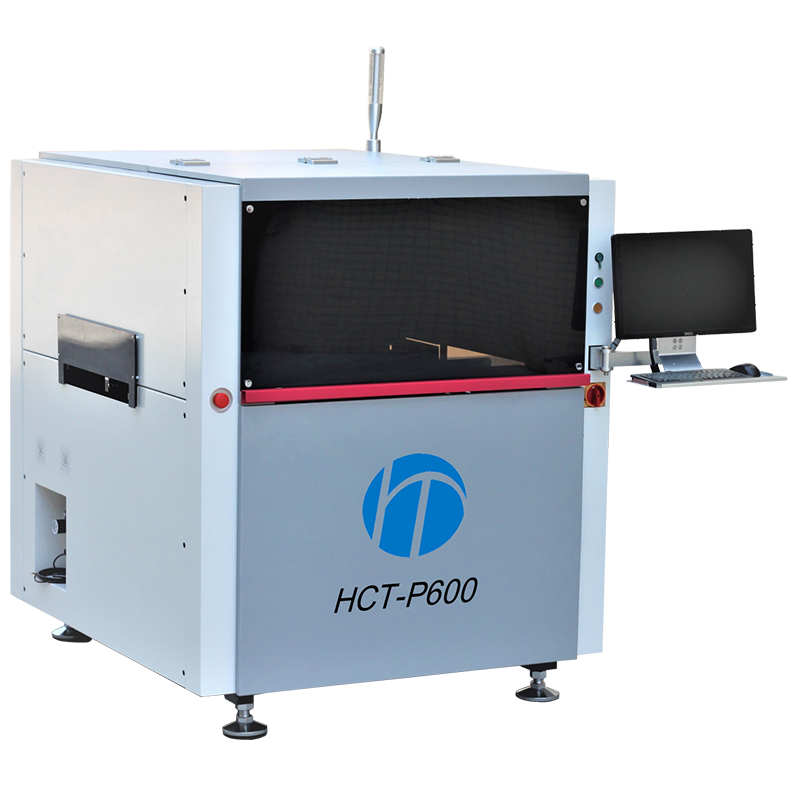

Different working files are loaded onto the SMT pick and place machine in order to attach the corresponding PCB. Please get in touch with us if you have any questions concerning the cost of a PCB pick and place machine, PCB soldering machine, PCB component placement machine, or PCB SMT assembly machine.

Technical Parameters - Automatic Copper Wire Lamp Placement Machine

|

Model |

HCT-WL10 |

|

|

Alignment |

Fixed Vision Alignment System |

|

|

Number of Spindles |

10 Spindles x 1 Gantry |

|

|

RatedPlacement Speed |

Group Picking & Group Placing |

LED0603 54,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Component Range |

Vision Alignment |

0603(inch)~5050~7474(mm) |

|

Max Height |

H=8mm |

|

|

Board Dimension(mm) |

Minimum |

50(L) x 50(W) |

|

Maximum |

1,000(L) x 380(W) |

|

|

Board Handling Method |

Inline Conveyor |

|

|

Tape Feeder |

Feeder Type |

ElectricFeeder |

|

Feeder Capacity |

20 (12mm) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm |

|

|

Utility |

Power |

AC 220V ±10% (50Hz, Single phase) |

|

Max3.2KW |

||

|

Air Consumption |

0.55-0.7MPa (5.6-7.1kgf/cm2) |

|

|

Mass |

Approx.1580kg |

|

|

External Dimension(mm) |

1,800(L) x1,150(D) x 1,450(H) |

|

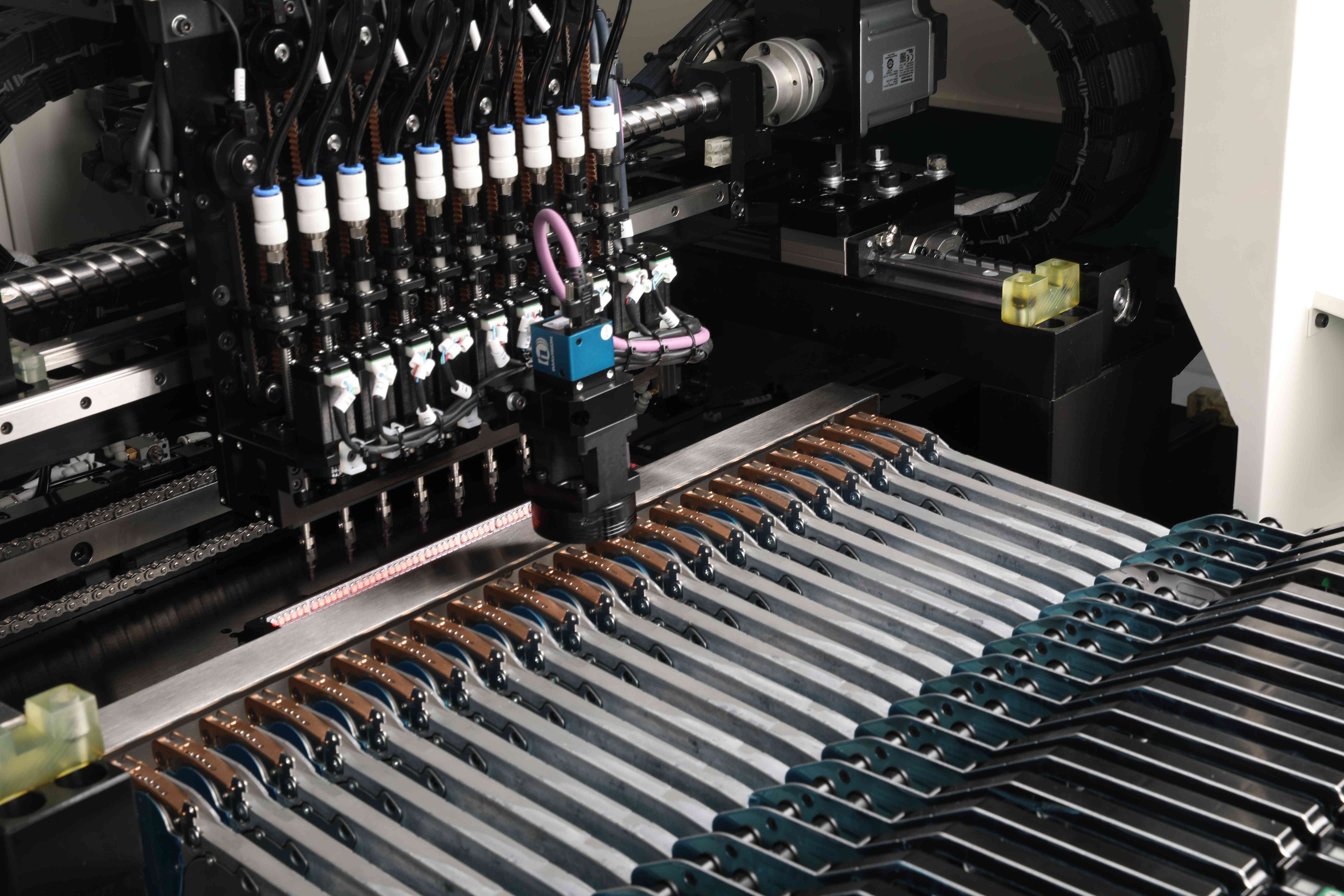

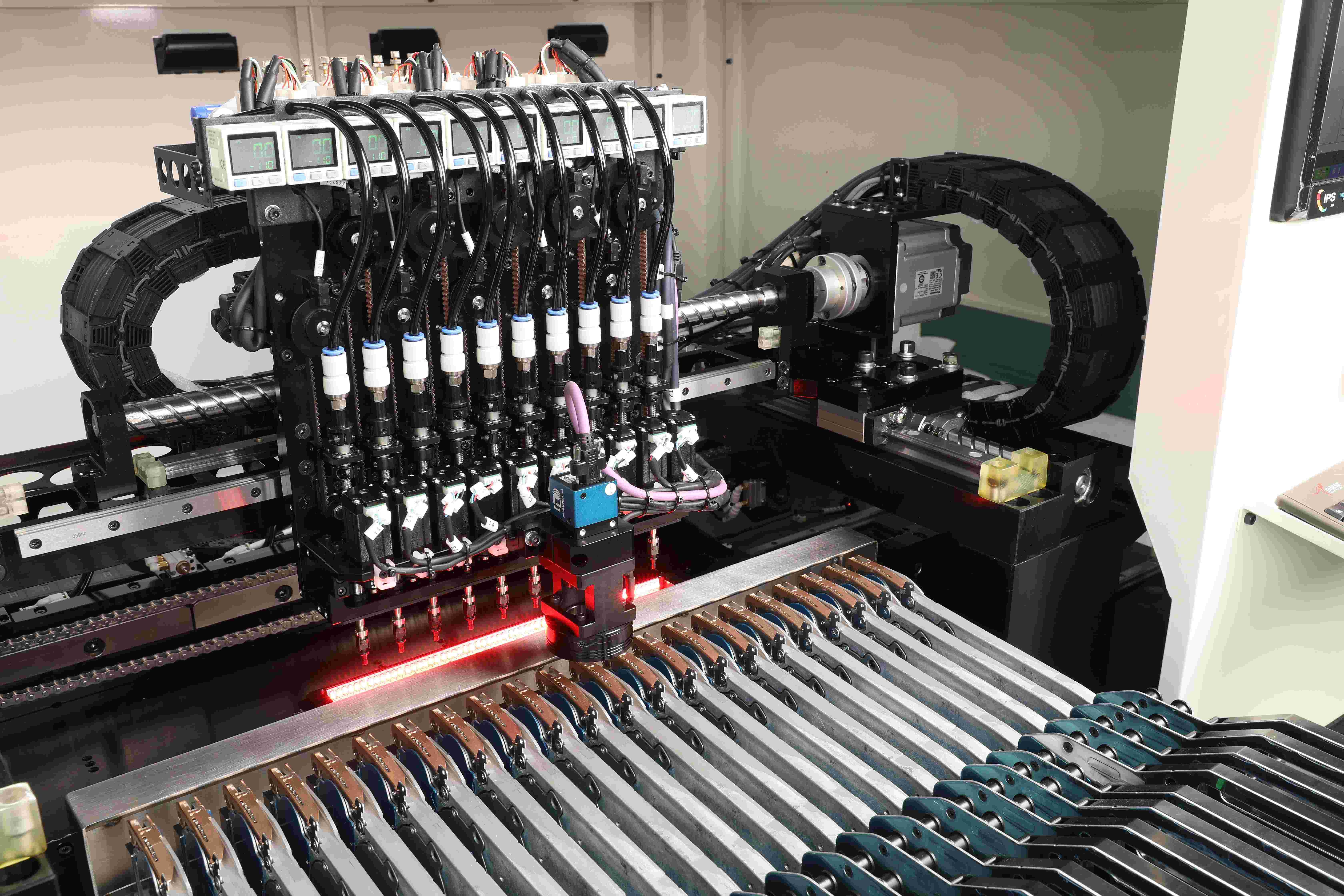

Product Features - Automatic Copper Wire Lamp Placement Machine

1. High accuracy: Each of the ten pick-up heads is equipped with a vision alignment camera to guarantee high accuracy. Using a high-resolution digital camera for fiducial recognition and programming.

2. Good stability: All the core hardware support by using international famous brands ensures placement stability, repeatability, and precision.

3. Leading efficiency: Single color, dual color, four colors, or five colors LED copper string lights can achieve group picking and group placing, a maximum speed of 54000CPH.

4. PCB Intelligent Transport: With a SMEMA-compatible inline conveyor for line automation, reduce manual intervention, and eliminate the deviation caused by the artificial.

5. Heavy marble platform support to ensure long service life.

6. Excellent quality hardware support by using international famous brands ensures placement repeatability and precision.

7. Self-developed software simplifies production, easy to operate, and programming.

Where The Pick And Place Equipment Is Used?

It loads different working files to mount the corresponding PCB. If you want to know more about the price of a PCB pick and place machine/ PCB soldering machine/ PCB component placement machine/ PCB SMT assembly machine, please contact us!

What Is The Difference Between SMT And SMD?

The difference between an SMD assembly machine and an SMT assembly machine is that SMD (surface mount device) refers to electronic components mounted on PCB. In contrast, SMT (surface mount technology) involves a method for placing electronic components on a printed circuit board.

Product Display - Automatic Copper Wire Lamp Placement Machine